MW Italia needed a greater integration and collaboration among the corporate plants in order to improve the performance related to quotation and new product development workflows. RuleDesigner was able to standardize workflows, support collaboration between the teams involved and ensure data traceability through a centralized document archive, which is organized for projects and job-orders.

CASE HISTORY

Planning of the workflow, support to collaboration and traceability of data from the request for an estimation to the management of the order for new product development.

RuleDesigner drives MW’s PLM prcesses

Download Business CaseOverview

Context of application

”What makes RuleDesigner so attractive is its “all-in-one” structure that has enabled effective information-sharing and an integrated and structured approach.

Ing. Emanuele ZanolliTechnical Product Manager MW Italia

COMPANY

MW - CLN GROUP

CLN operates in the steel sector since 1948. Today the Group, with its production sites and business centers, is one of the leading international players on the world market of processing, stamping and assembly of metal components for the automotive business and steel wheels. is present in the processing and marketing of flat laminated steel for various user sectors including the car industry – from the stamping and assembly of structural parts and vehicle components to steel wheels for all vehicle types and from the world of domestic electrical appliances to earth moving machinery and, in general, to all fields using steel.Furthermore, the company is also present in the steel re-rolling industry and in the European market for the distribution of flat steel products.

The Group is constantly committed to the industrialization and the development of new products, as well as to consolidate business relations with customer, paying attention to high quality steel and innovation.

MW is the steel wheel market leader for all vehicle types.

Divisione MA

MA is the CLN Group Company specialized in producing and assembling steel automotive structural parts, components, subassemblies and modules. It is present in Europe, Turkey, South Africa and Latin America and it has important partnership in China and in India.

Divisione MW

MW is the steel wheel market leader for all vehicles types. It is one of the main producer of wheel rims for motorcycles that provides complete engineered wheels solutions to customers. It has plants in Europe, Russia, Japan, South Africa and joint venture in Turkey, China, Malesia and Mexico.

MW CONTEXT, THE WHEEL DIVISION

Main features of the industry

MW is the steel wheel market leader for all vehicle types. Each model is designed, tested and manufactured with the guarantee of top safety standards for both production workers and vehicle users.

Every single product is developed with a systemic approach, together with the customer. Starting from the virtual analysis of the piece to its industrialization, from the planning of production to the investment, up to the choice of the production site.

The first step is the analysis that aggregates the customer requests together with evaluations and variables consolidated over time by the internal design team. Then, it moves on by simulating calculations, production processes and the behavior of the wheel on the road. In this regard, MW has cutting-edge laboratories with innovative technology and equipment, which are able to simulate any environmental condition, road surface as well as wheel wear and load tests (www.toprovelab.com).

Reference Market

The main reference market of the Group is represented by manufactures of cars and light commercial vehicles (Original Equipment Manufactures- OEM). On this market operate MA and MW divisions as direct suppliers of components mainly made of steel. A smaller part of the production, mainly steel wheels, is addressed to the market of the so-called secondary equipment (aftermarket).

The market for the supply of automotive components to OEMs is characterized, for both wheel production and formed parts, by strong competition and from customer requests of progressive price reduction during the lifecycle of the models produced.

The level of competition and discounts to customers can reduce the profitability of the Group if they are not absorbed by a continual efficiency improvement.

CHALLENGES

Challenges faced during the deployment of RuleDesigner

The main challenge was managing change across the Group. In fact, with different production plants worldwide, the Group needed a structured and global approach aimed to the transition from an incomplete management of workflows to a performing one, able to integrate projects teams and stakeholders.

- Supporting collaborative processes between users of different age, background, functions and nationalities belonging to six branches across the world.

- Finding a common path to be accepted by both technical and sales functions, overcoming the aversion to change and to the adoption of appropriate technologies.

PROCESS

Corporate process subjected to change

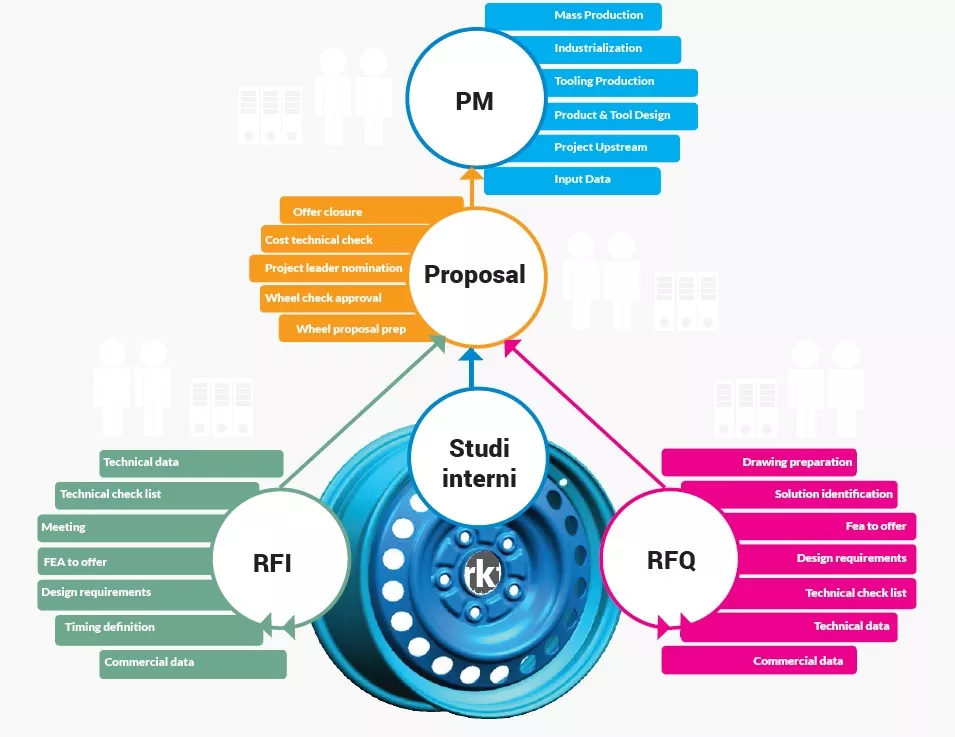

MW deals with the design and production of steel wheels for private and commercial vehicles, directly interfacing with the manufactures of vehicles. Below, the macro workflow to request the estimation of new products.

Any time a new quotation request is issued by the customer, the customer service collects technical and sales information and define the customer requirements. Then, it passes them to the technical office for figuring out one or more solutions. The technical solutions are quoted by the sales department and discussed with the customers, from both a commercial and technical point of view.

operational processes

From an operational point of view, there was a lack of clear planning of workflows, able to coordinate tasks to be carried out by the different branches across the world.

Informative problem

Regarding the informative aspect, they had not a centralized repository able to collect all the documents and the history of each project, nor for the one manufactured nor for the just estimated ones.

GOALS

Introducing a technology to support the change process

In order to successfully face challenges in a dynamic, competitive sector characterized by the continuous research for high quality standard products, the company has overtaken a change process for a homogenous and structured work methodology.

In this regard, it was necessary to introduce modern technologies able to support the organization of the team work, the worldwide collaboration, the traceability of data and the control to monitor the efficiency and the effectiveness of the processes.

WHY RULEDESIGNER

Some of the reasons that have brought the customer to choose RuleDesigner solution

INFOGRAPHIC

Data based on 3 years

1100

60

4400

6 plants cooperate along the workflows

150

700

200

PROJECT

From the request for cost estimation to order for new product development

RuleDesigner made possible to map the workflows that go from the cost estimation to the management of the job order for new product development, organizing them in macro-phases (sub-projects). Specifically, there have been identified and mapped RFQ (request for quotation) and RFI (request for information) processes, Proposal and Project Management workflows, too.

RuleDesigner guarantees that all the steps that have been predefined for each type of process are covered and allows to have a complete visibility on the execution status of the various processes, of the people and plants involved and related responsibilities.

The project documents, of over 60 different types, are filed in one single container and available for consultation by all the plants with regulated access based on the rights of groups and users.

SPONSOR OF CHANGE

Technical and Sales Divisions

The sponsors for the change process were the technical and sales divisions, that had the goal to realize the plan and coordinate the tasks for the introduction of corrective actions.

The project manager, a resource with technical and commercial skills and therefore able to gather the different classes of needs and bring them back to an integrated workflow system, coordinated all the project tasks and lead people toward the target goals.

The winning strategy was to share workflows with stakeholders involved in the process, optimizing them on the basis of the suggestions received and thus building an agreement throughout different levels and company functions.

”RuleDesigner project allowed me to grow professionally, allowing me to have a broader vision of our business, adding to the technical point of view also the commercial one.

Ing. Davide LorussoOperations Manager for the RuleDesigner project - MW ITALIA

"*" indicates required fields